Definition of Pattern Part-2

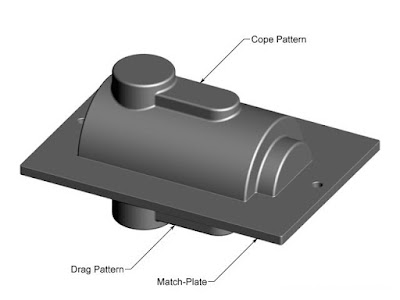

4. Match Plate Pattern:

|

Match Plate Pattern |

Basically Match plate pattern may be a split pattern. Cope and drag areas are on the other faces of metallic plate. This metallic plate is termed as Match Plate. This sort of pattern requires very less diligence and provides very high output. Because the gates and runners also are on the match plate. this is often utilized in various manufacturing industries. This is often very expensive and provides accuracy also as high yield. This pattern is widely used for casting metals like aluminium.

5. Gated Pattern:

|

Gated Pattern |

Gated sorts of patterns are wont to make multiple components inside the only mold. Gated pattern is nothing but the pattern consisting one or more patterns. For joining different patterns gates are used. These are loose patterns where gates and runners have already attached. These patterns are very expensive. Thanks to their high cost they're used for creating small castings. These small castings further are utilized in molding machines also as in mass producing processes.

6. Skeleton Pattern:

|

Skeleton Pattern |

Skeleton pattern is employed for castings which have simple size and shape. These castings are usually large in size. The sole disadvantages of skeleton sorts of patterns are – it's applicable for little number of components and it's not cheap. Economically, it's not the simplest pattern. Stickler is employed to get rid of extra sand. These are nothing but frames of wood that highlight the world which is to be cast. These patterns also help molder. They’re widely utilized in process of pit or floor welding.

Comments

Post a Comment