Definition and Classification of Keys

Definition of Key:

Key is a part of a machine or equipment

where it is used to connect the rotating machine element (Hub/Pulley) to the

shaft and enables the torque transmission. The key will have a provision in

both the shaft and therefore the machine element which needed to be connected.

This is called Keyway.

Types of Keys:

Following are the different types of

keys:

1. Sunk Keys

i.

Rectangular Sunk key

ii. Square Sunk Key

iii. Parallel Sunk Key

iv.

Gib Headed Sunk Key

v.

Feather Sunk Key

2. Saddle Keys

i.

Flat saddle key

ii.

Hallow saddle Key

3. Tangent Keys

4. Round Keys

5. Splines

1. Sunk Keys:

When a key is provided with the half

portion in the shaft and the other half portion in the hub, then the key is

known as the Sunk Key.

There are different varieties in the

sunk key.

The rectangular sunk key's nothing but

having the oblong cross-section. The size of the key will be based on the diameter

(d) of the shaft (Or the diameter of the Bore in the hub).

ii) Square Sunk Key:

The Square sunk key is nothing but having the

Square cross-section.

iii) Parallel Sunk Key:

When a square sunk key or the oblong sunk key

having the uniform cross-section with none taper then it are often called as

“the parallel sunk key”. But in the above mentioned the Square sunk key or the

Rectangular sunk key they will be having the taper along the length of the key.

iv) Gib Head Key:

Simply a rectangular sunk key with a

head to facilitate the easy removal is known as the Gib-headed key. as simple

as that.

v) Feather Sunk Key:

A feather key's a parallel key which

is fastened to at least one part (Hub/shaft) with help of the screws called the

feather key. Sometimes a double gib-head key are often a fether key by locking

it the one part (hub/shaft).

vi) Woodruff Key:

The woodruff key's during a piece from

the cylindrical disc as shown within the Figure, and its main advantage is that

it are often adjustable, tilt within the keyway or keyseat.

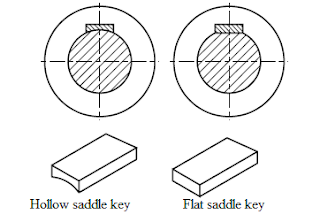

2. Saddle Keys:

These sort of keys are rarely used

because these cannot transmit the high torque. Saddle won’t have the supply

within the shaft; instead, it holds the shaft by friction. Saddle key has two

variants.

i) Flat saddle key:

A flat saddle key is taper key and

having a provision in the hub only and will be floated on the shaft and hold

the shaft by means of the friction. So it can be used for light loads. It used

for temporary fastening only.

ii) Hallow saddle Key:

A Hallow saddle key is also a taper

key here also it will have the provision in the hub only, but the contact

portion of the key with the shat will be shaped into a curvature to get the

full grip on the shaft for better friction.

3. Tangent Keys:

Tangent keys are used in heavy-duty

equipment. Tangent keys are actually a pair. These pair of keys are placed right

angles to each other and tangent to the surface of the shaft as shown in the

figure. Each key will withstand the torsion in one direction only.

4. Round Keys:

Round keys are circular in section and

fit into the holes. The round keys will be placed half portion hole in the

shaft and the other half portion hole in the hub as shown in the fig. These

sort of shaft keys are usually prepared for the low power drives.

5. Splines:

All the above-mentioned keys are

individual parts. What happens when the keys are integral parts of the shaft or

hub? That what we called as the Splined shafts. These are utilized in the

special applications like where we've to transmit the torque larger in portion

than the shaft size.

Comments

Post a Comment