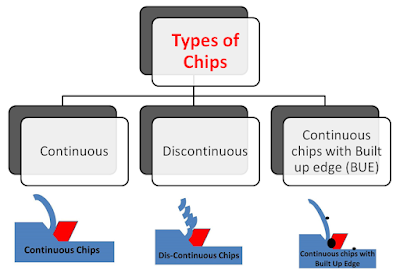

Types of Chips

Types of chips:

Following

are the three common types of chip from a single point tool:

Continuous

chips are formed by the continual plastic deformation of metal without fracture

ahead of the leading edge of the tool and is made by the graceful flow of the

chip up the tool face. MS steel and copper are considered to be most desirable

materials for obtaining continuous chips. The chips obtained have same

thickness throughout. This type of chip is the most desirable. Since its stable

cutting, leading to generally good surface finish. On the opposite hand these

chips are difficult to handle and dispose off.

Continuous

chips tend to be formed when the subsequent condition exist:

•

Ductile material

•

High cutting speed

•

Small chip thickness

•

Large rack angle

2. Discontinuous or Segmental

chip:

This

type of chips are made by a series of rupture occurring approximately

perpendicular to the tool place face each chip element passing off along the

tool face the chip element in the form of small segment may adhere loosely to

every other and becomes slightly longer.

Since

the chips hack into small segments the friction between the tool and thus the

chips reduces’ resulting in better surface finishing. These chips are

convenient to collect handle and dispose off. Discontinuous chips tend to be

formed when one or more or the subsequent conditions exist:

•

Brittle material, such as cast iron and bronze.

•

Large chip thickness

• Low

cutting speed

•

Small rack angle

Discontinuous

chips also are produced when cutting more ductile material with the utilization

of a cutting fluid.

3. Continuous Chip with Built up

Edge:

This

type of chip is extremely almost like the continual chip. With the difference

that it's a built up edge adjacent to tool face and also it's not so smooth. It

is obtained by machining on ductile material, during this condition of high

local temperature and extreme pressure within the cutting and high friction

within the tool chip interference, may cause the work material to stick or weld

to the leading edge of the tool. Successive layers of labor material are then

added to the built up edge. When this edge becomes larger and unstable, it

breaks up and a part of it's carried up the face of the tool along side the

chip while the remaining is left over the surface being machined, which

contributes to the roughness of the surface. The built up edge changes its size

during the cutting operation. It first increases, then decreases, and then

again increases etc.

Comments

Post a Comment